- DSB has adopted Desktop Metal’s complete X-Series metal binder jetting lineup, along with Live Sinter™ simulation and correction software, at its Wisconsin headquarters, which processes more than eight million pounds of powder into parts annually with both traditional and additive technologies

- The X-Series line from Desktop Metal features Triple Advanced Compaction Technology (ACT) and includes the entry-level InnoventX, midsized X25Pro and extra-large X160Pro

- DSB says that Desktop Metal’s Live Sinter software is a critical, trusted element of its metal binder jetting package. The powerful multi-physics simulation tool predicts and corrects for sintering deformation, delivering sinter-ready printable geometries in minutes

- Desktop Metal is the world’s leader in metal binder jetting with six printer models offering different sizes and capabilities, as well as the world’s largest portfolio of 21 metal materials, including stainless steels, precious metals, titanium, aluminum and more

- Aside from the X-Series, DM’s metal binder jet lineup also includes the entry-level Shop System, the P-1 research and development printer, and the Production System P-50 the world’s fastest metal binder jetting system, offering the lowest unit cost in binder jetting

Desktop Metal, Inc. (NYSE: DM), a global leader in additive manufacturing technologies for mass production, today announced that Wisconsin-based DSB Technologies (DSB), a leader in high-quality metal part production with sinter-based technologies such as powder metallurgy (PM) and metal injection molding (MIM) has now adopted the complete X-Series metal binder jetting product lineup, including Live Sinter software, from Desktop Metal.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230912869954/en/

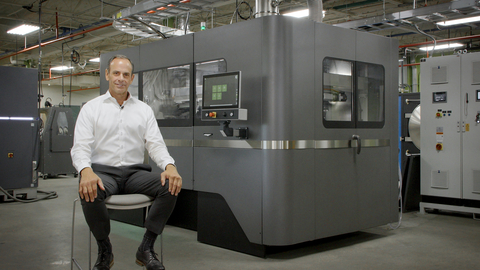

Paul Hauck, Chief Operating Officer for DSB Technologies, based in Janesville, Wisconsin, explains why the company has adopted the entire line of Desktop Metal X-Series metal binder jetting 3D printers for production of metal parts. Behind Hauck are the Desktop Metal X160Pro and, far left, the X25Pro. DSB is an experienced producer of metal parts with sinter-based technologies such as metal injection molding (MIM) and powder metallurgy (PM) — processing more than eight million pounds of powder into parts annually. (Photo: Business Wire)

As shown in a new customer video, DSB is now developing and delivering customer parts with the InnoventX, X25Pro and X160Pro from Desktop Metal for a range of metals, including 316L and 17-4PH stainless steels, 4140 and M2 Tool Steel. It also plans to adopt Desktop Metal binder jetting for aluminum in the future. The video is available at TeamDM.com/DSB.

“Binder jetting really is a forming technology that gives us unlimited design potential,” said Paul Hauck, Chief Operating Officer for DSB Technologies. “We can go from a very simple shape to very complex things you can’t produce in hard tooling, taking complexity beyond what’s possible with metal injection molding. Binder jetting creates applications never produced before, and we want to be a leader in that.”

Based in Janesville, Wisconsin, DSB is home to more than 30 high-temperature continuous sintering furnaces — believed to be North America’s largest installed capacity — as well as post-processing technology to support volume production in metal binder jetting. Of the eight million pounds of metal powder processed by DSB annually, about 90% are grades of stainless steel. DSB currently serves the aerospace, automotive, defense, electronics, industrial, medical, and sports equipment markets.

What is Metal Binder Jetting?

In binder jetting, an industrial printhead selectively deposits a binder into a bed of powder metal particles creating a solid part one thin layer at a time. When printing metal powders, the final bound metal part must be sintered in a furnace to fuse the particles together into a solid object. DM printers deliver high densities of greater than 97% for most metals, in line or better than MIM or gravity castings, depending on the metal. To learn more, download the Ultimate Guide to Metal Binder Jetting at TeamDM.com/BinderJetGuide.

Binder jet 3D printing technology is widely viewed as a desirable and sustainable production method, largely because of its high speed, low waste and cost, as well as material flexibility. DM printers also binder jet sand and ceramics in high-volume, serial production applications today.

“The exciting part about binder jetting is the path from concept to part is all digital,” Hauck said. “You're not sending a CAD file over to a tool shop that then creates a reverse image. So, you're taking as few as eight weeks, and maybe as many as 16 or 20 weeks, out of that process.”

DSB has been phasing in Desktop Metal’s binder jetting technology over the past few years. First installed in 2021, the InnoventX lab-sized printer is used for material development and testing initial sintering parameters. The X25Pro, installed in 2022, allows the team to scale those successful tests up to application development in a mid-size machine that is also capable of bridge production. The X160Pro, installed in 2023, offers the largest build volume to take applications to serial production.

Live Sinter™ Simulation Software is Critical

While the PM and MIM sectors have long operated with trial and error when sintering powder metal parts, Live Sinter is changing the game of what’s possible with powder metal production.

Hauck said the software is highly effective in reducing iterations and saving time. “We now have very useful scientific analytical tools that enable successful outcomes,” Hauck said. “It's helping us solve application problems, get successful outcomes, and get there faster.”

To learn more about metal binder jetting with DSB Technologies, visit www.dsbtech.com

About Desktop Metal

Desktop Metal (NYSE:DM) is driving Additive Manufacturing 2.0, a new era of on-demand, digital mass production of industrial, medical, and consumer products. Our innovative 3D printers, materials, and software deliver the speed, cost, and part quality required for this transformation. We’re the original inventors and world leaders of the 3D printing methods we believe will empower this shift, binder jetting and digital light processing. Today, our systems print metal, polymer, sand and other ceramics, as well as foam and recycled wood. Manufacturers use our technology worldwide to save time and money, reduce waste, increase flexibility, and produce designs that solve the world’s toughest problems and enable once-impossible innovations. Learn more about Desktop Metal and our #TeamDM brands at www.desktopmetal.com.

About DSB Technologies

DSB Technologies is your leading metallurgical solutions partner for the concept, design, and production of complex, high performance powder metal components. Our talented team of more than 400 technical experts enable our global customer base to lead their industries with new technology that promotes a sustainable future and rethinks technology norms. In our commitment to innovation, we are aggressively pioneering advanced press and sinter powder metallurgy, metal injection molding and metal 3D printing processes to unlock the full potential for material and product development.

Forward-looking Statements

This press release contains certain forward-looking statements within the meaning of the federal securities laws. Forward-looking statements generally are identified by the words “believe,” “project,” “expect,” “anticipate,” “estimate,” “intend,” “strategy,” “future,” “opportunity,” “plan,” “may,” “should,” “will,” “would,” “will be,” “will continue,” “will likely result,” and similar expressions. Forward-looking statements are predictions, projections and other statements about future events that are based on current expectations and assumptions and, as a result, are subject to risks, uncertainties. Many factors could cause actual future events to differ materially from the forward-looking statements in this document, including but not limited to, the risks and uncertainties set forth in Desktop Metal, Inc.'s filings with the U.S. Securities and Exchange Commission. These filings identify and address other important risks and uncertainties that could cause actual events and results to differ materially from those contained in the forward-looking statements. Forward-looking statements speak only as of the date they are made. Readers are cautioned not to put undue reliance on forward-looking statements, and Desktop Metal, Inc. assumes no obligation and does not intend to update or revise these forward-looking statements, whether as a result of new information, future events, or otherwise.

View source version on businesswire.com: https://www.businesswire.com/news/home/20230912869954/en/

Contacts

Investor Relations

Jay Gentzkow

(781) 730-2110

jaygentzkow@desktopmetal.com

Media Relations

Sarah Webster

sarahwebster@desktopmetal.com

(313) 715-6988

DSB Technologies

Kayla Hagan, Marketing Manager

Khagan@dsbtech.com